1. Introducción

This manual provides essential information for the safe and effective installation, operation, and maintenance of the Protech 62-24268-03 Integrated Furnace Control Board. This control board is designed to manage the various functions of a furnace, ensuring proper heating system performance. Please read all instructions thoroughly before proceeding with any installation or service.

2. Información importante de seguridad

ADVERTENCIA: La instalación, ajuste, alteración, servicio o mantenimiento inadecuados pueden causar daños a la propiedad, lesiones personales o la muerte. La instalación y el servicio deben ser realizados por un instalador calificado, una agencia de servicio o el proveedor de gas.

- Always disconnect electrical power to the furnace before servicing.

- Ensure gas supply is turned off before working on gas components.

- Utilice equipo de protección personal (EPP) adecuado durante la instalación y el servicio.

- Verifique que todas las conexiones del cableado sean seguras y correctas según el diagrama de cableado.

- No omita ningún dispositivo de seguridad.

- Keep the area around the furnace clear of combustible materials.

3. Producto terminadoview

The Protech 62-24268-03 is an integrated furnace control board designed for specific Rheem/Ruud furnace models. It serves as the central control unit for the furnace's operational sequences, including ignition, flame sensing, and blower motor control.

3.1 Contenido del kit

This kit typically includes the following components:

- 1 x 62-102635-01 Integrated Furnace Control Board

- 1 x 90-24314-04 Wiring Diagram

- 1 x 92-26177-555 Instruction Sheet

- 1 x AS-50208-31-CY Wire Assembly

3.2 Dimensiones del producto

The control board measures approximately 8.8 inches (L) x 2.4 inches (W) x 7.4 inches (H).

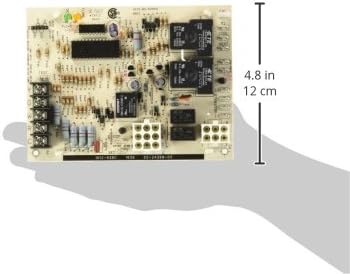

Image: The Protech 62-24268-03 Integrated Furnace Control Board, shown with approximate dimensions of 4.8 inches (12 cm) in width, indicating its compact size for furnace integration.

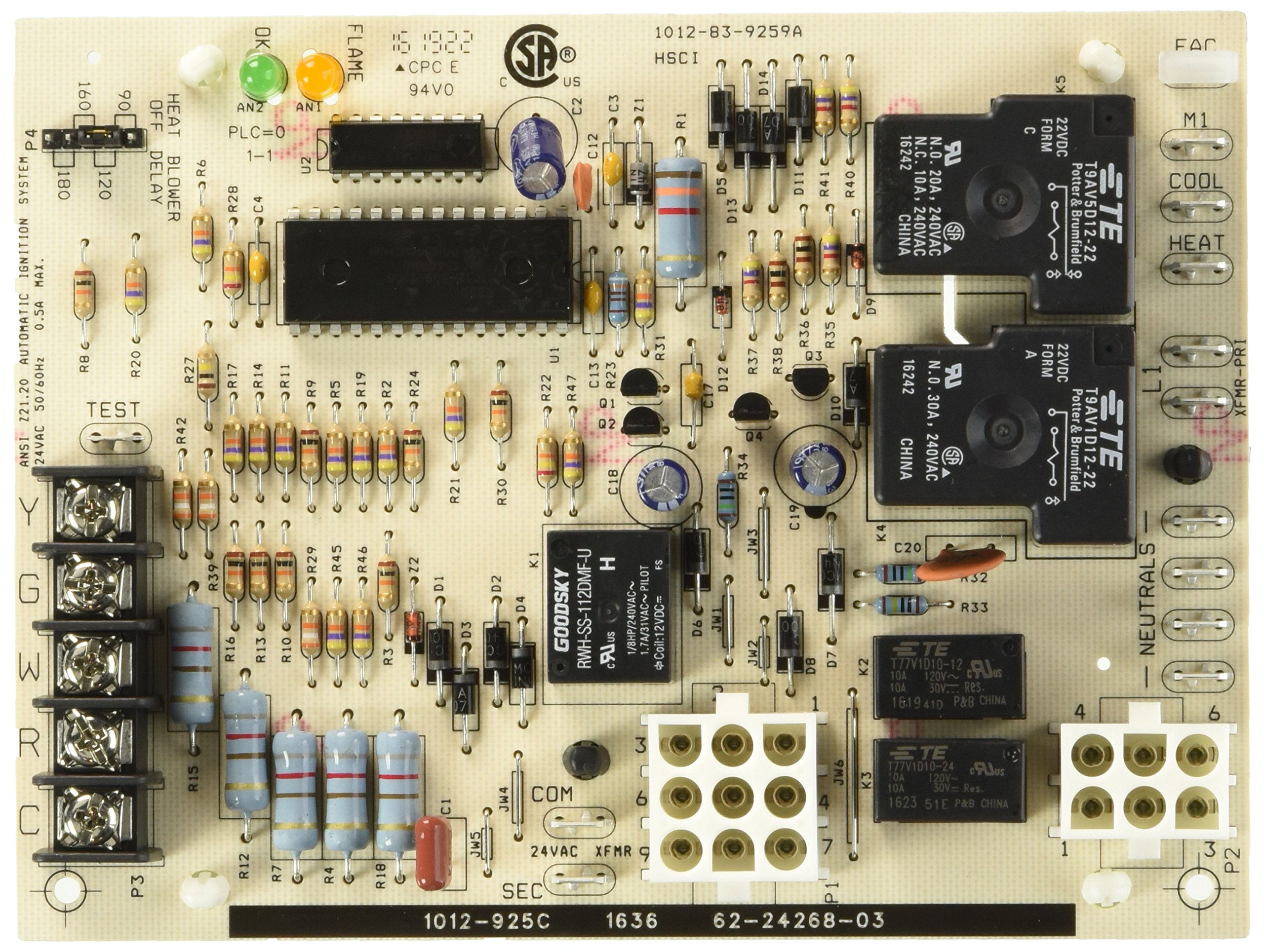

Imagen: Un detalle view of the Protech 62-24268-03 Integrated Furnace Control Board, highlighting its various electronic components, relays, and wiring terminals.

4. Instrucciones de instalación

NOTA: All controls should be installed by a licensed professional. Failure to read and follow all instructions carefully before installing or operating this control could cause personal injury and/or property damage.

4.1 Compatibilidad

This control board is compatible with the following Rheem/Ruud models:

- RGLK - All models

- RGLQ - Models with gas code: FJ, FO, GO

- RGPK - All models

- RGPQ - Models with gas code: FJ, FO, GO

- UGLK - All models

- UGLQ - Models with gas code: FJ, FO, GO

- UGPK - All models

- UGPQ - Models with gas code: FJ, FO, GO

The gas code refers to the first two digits of the unit's serial number.

4.2 Pasos previos a la instalación

- Desconectar la energía: Apague toda la energía eléctrica del horno en el panel de servicio principal.

- Turn Off Gas: Close the manual gas shut-off valve to the furnace.

- Placa de control de acceso: Abra el panel de acceso del horno para ubicar la placa de control existente.

- Cableado de documentos: Carefully label all wires connected to the old control board before disconnecting them. Take photos for reference if necessary.

4.3 Reemplazo de la placa

- Quitar el tablero antiguo: Disconnect all labeled wires and mounting screws from the old control board. Carefully remove it.

- Instalar nueva placa: Mount the new Protech 62-24268-03 control board in the same location as the old one, securing it with screws.

- Conectar el cableado: Reconnect all wires to the new board according to your labels and the provided wiring diagram (90-24314-04). Ensure all connections are firm and correct.

- Wire Assembly: Utilize the AS-50208-31-CY wire assembly as needed for proper connections.

4.4 Pasos posteriores a la instalación

- Panel seguro: Cierre y asegure el panel de acceso del horno.

- Restore Gas: Open the manual gas shut-off valve.

- Restaurar energía: Turn on electrical power to the furnace at the main service panel.

- Operación de prueba: Initiate a heating cycle from the thermostat to verify proper furnace operation. Observe the ignition sequence and ensure the furnace operates as expected.

5. Operación

The Protech 62-24268-03 Integrated Furnace Control Board automatically manages the furnace's heating cycle. Once installed and powered, it will:

- Receive a call for heat from the thermostat.

- Initiate the inducer motor to purge combustion gases.

- Activate the igniter to light the main burners.

- Monitor the flame presence via the flame sensor.

- Engage the main blower motor to distribute heated air.

- Shut down the heating cycle when the thermostat's set point is reached.

The board also incorporates safety features to prevent operation under unsafe conditions, such as flame failure or overheating.

6. Mantenimiento

The Protech 62-24268-03 Integrated Furnace Control Board is designed for reliable operation and generally requires no specific maintenance. However, regular professional furnace maintenance is crucial for the overall health of your heating system.

- Ensure the furnace area remains clean and free of dust and debris.

- Have your furnace inspected annually by a qualified HVAC technician. This includes checking electrical connections, cleaning components, and verifying proper operation of all safety devices.

- Do not attempt to clean the control board with liquids or abrasive materials.

7. Solución de problemas

Many furnace control boards include diagnostic LED lights that flash codes to indicate specific issues. Refer to your furnace's specific diagnostic chart (often found on the furnace cover) in conjunction with the control board's instruction sheet (92-26177-555) for detailed troubleshooting.

Problemas comunes y consejos generales:

- Sin calor: Check thermostat settings, ensure power and gas supply are on. Look for diagnostic codes on the control board.

- Operación intermitente: Could indicate a loose connection, a failing sensor, or an intermittent fault on the board.

- El soplador no funciona: Check for thermostat fan settings, or issues with the blower motor or its relay on the board.

- Repeated Ignition Lockout: Often related to flame sensor issues, gas supply problems, or igniter malfunction.

If you are unable to resolve an issue, contact a qualified HVAC technician for assistance. Do not attempt repairs beyond your skill level, as this can lead to further damage or safety hazards.

8. Especificaciones

| Característica | Detalle |

|---|---|

| Marca | Tecnología Pro |

| Nombre del modelo | 62-24268-03 |

| Característica especial | Tablero de control integrado |

| Usos específicos | Furnace operation, heating systems |

| Volumentage | 120 voltios |

| Vol. Aceptadotage Frecuencia | 100 a 120 voltios y 60 hercios |

| Quétage | 2 vatios |

| Dimensiones del producto | 2.25"W x 7.4"H (Board only, approximate) |

| Peso del artículo | 7.4 onzas |

| Material | Metal |

| Especificación cumplida | UL, cUL |

| Componentes incluidos | Integrated Furnace Control Board (IFC) |

9. Garantía y soporte

9.1 Información de garantía

Unless otherwise noted, all items carry a one-year limited warranty from the date of purchase. Please retain your proof of purchase for warranty claims.

9.2 Atención al cliente

For technical assistance, troubleshooting beyond this manual, or warranty inquiries, please contact your authorized ProTech dealer or a qualified HVAC professional.