1. Producto terminadoview

The WAGO 8001-001/K010-9890/0000-0400 is an industrial interface module designed for reliable electrical connections in various applications, including prototyping boards and semiconductor product interfaces. This module facilitates secure and organized wiring within industrial electrical systems, ensuring efficient signal and power distribution.

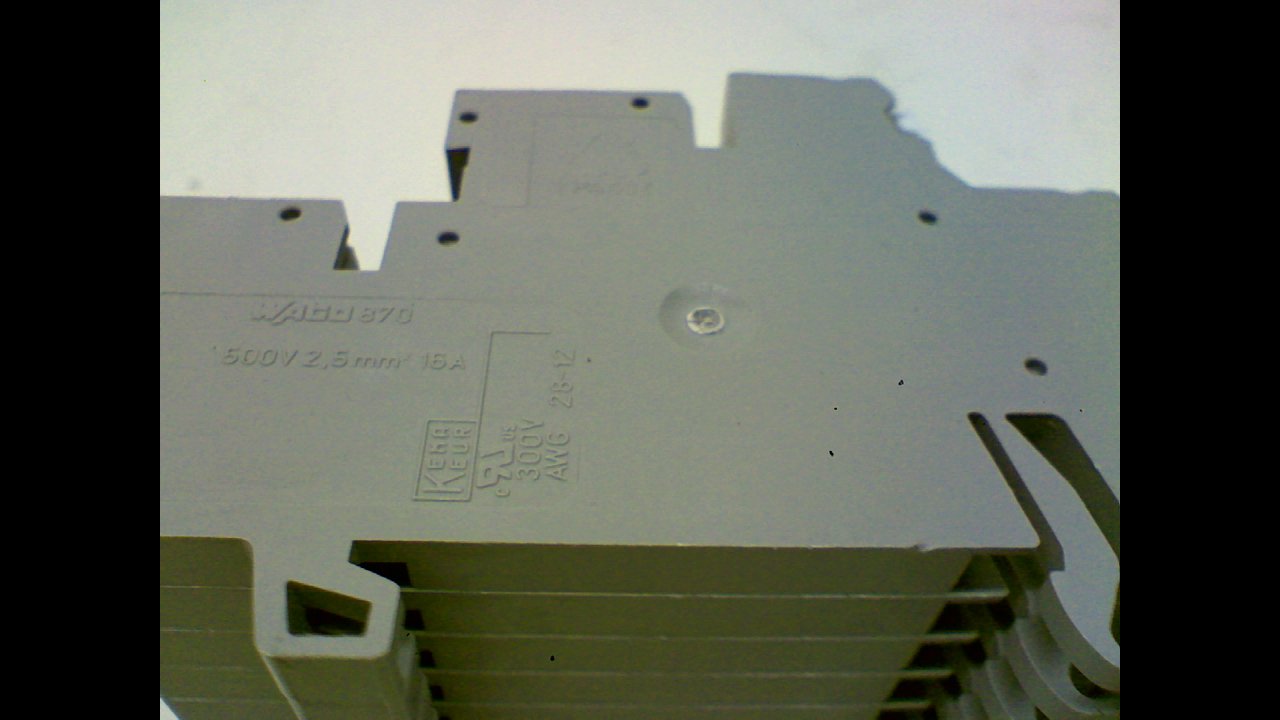

Figura 1: De cerca view of the WAGO 8001-001/K010-9890/0000-0400 industrial interface module, displaying its model number and electrical specifications such as 500V/2.5mm² 16A. This image highlights the detailed markings on the side of the module.

2. Información de seguridad

Lea y comprenda todas las instrucciones de seguridad antes de instalar, operar o realizar el mantenimiento de este producto. El incumplimiento de estas instrucciones podría provocar descargas eléctricas, incendios, lesiones graves o la muerte.

- Personal calificado: La instalación y el mantenimiento deben ser realizados únicamente por personal calificado y autorizado.

- Desconexión de energía: Always disconnect power to the circuit before working on the module or making any connections. Verify that power is off using appropriate testing equipment.

- Herramientas adecuadas: Utilice únicamente herramientas aisladas adecuadas para trabajos eléctricos.

- Condiciones ambientales: Ensure the operating environment is free from excessive moisture, dust, corrosive gases, and extreme temperatures.

- Normas de cableado: Adhere to all local and national electrical codes and standards.

3. Configuración

Proper setup is crucial for the reliable operation of the WAGO interface module.

3.1 Montaje

- Select a suitable mounting location within the control cabinet or enclosure, ensuring adequate space for wiring and ventilation.

- Mount the module securely onto a DIN rail using its integrated mounting mechanism. Ensure it clicks firmly into place.

- Verify that the module is stable and will not vibrate loose during operation.

3.2 conexiones de cableado

The module features multiple connection points for various signals and power lines.

- Identify the appropriate terminals for your application (e.g., input, output, power, ground). Refer to your system's wiring diagram.

- Strip wire insulation to the recommended length (typically 8-10 mm) to ensure proper contact without exposed conductors.

- Insert the stripped wire into the designated terminal opening.

- Accione el clamping mechanism (e.g., push-in or lever) to secure the wire firmly. Gently pull on the wire to confirm it is properly seated and cannot be easily dislodged.

- Repeat for all necessary connections, ensuring correct polarity and signal assignment.

Figura 2: Lado view of the WAGO 8001-001/K010-9890/0000-0400 module, illustrating its multi-level design which allows for high-density wiring in a compact form factor. This view helps in understanding the physical dimensions and structure for mounting.

Figura 3: De arriba hacia abajo view of the WAGO 8001-001/K010-9890/0000-0400 module, providing a clear perspective of the numbered connection points. This view is essential for accurate wiring and identification of individual terminals.

4. Instrucciones de funcionamiento

Once properly installed and wired, the WAGO interface module operates passively, providing reliable electrical connections. Its primary function is to serve as a robust and organized interface for signals and power within an industrial control system.

- Aplicación de potencia: After all connections are verified, apply power to the circuit.

- Flujo de señal: Signals and power will pass through the module according to your system's design.

- Escucha: Monitor connected devices for proper operation. The module itself does not require active control or programming.

5. Mantenimiento

The WAGO interface module is designed for minimal maintenance. Regular inspections are recommended to ensure continued reliable operation.

- Inspección visual: Inspeccione periódicamente el módulo para detectar cualquier signo de daño físico, decoloración o conexiones sueltas.

- Integridad de la conexión: Ensure all wires remain securely fastened in their terminals. Re-tighten or re-insert any loose connections after disconnecting power.

- Limpieza: If necessary, gently clean the module with a dry, lint-free cloth. Do not use solvents or abrasive cleaners. Ensure power is disconnected before cleaning.

- Comprobación ambiental: Verify that the operating environment continues to meet the specified conditions (temperature, humidity, absence of contaminants).

6. Solución de problemas

Si encuentra problemas, considere los siguientes pasos de solución de problemas:

- No Signal/Power:

- Verifique que se suministre energía al circuito.

- Check all connections to and from the module for proper seating and continuity.

- Ensure correct wiring according to your system diagram.

- Conexión intermitente:

- Inspect for loose wires or damaged insulation.

- Ensure wires are stripped to the correct length and fully inserted into the terminals.

- Daño físico:

- If the module shows signs of physical damage (e.g., cracks, burns), it should be replaced immediately.

If problems persist after following these steps, consult a qualified electrician or contact WAGO technical support.

7. Especificaciones

| Atributo | Valor |

|---|---|

| Número de modelo | 8001-001/K010-9890/0000-0400 |

| Fabricante | WAGO |

| ASIN | B0115HA4E |

| Fecha de primera disponibilidad | 7 de julio de 2015 |

| Aplicación típica | Industrial Electrical, Semiconductor Interfaces, Prototyping |

8. Garantía y soporte

For specific warranty information regarding the WAGO 8001-001/K010-9890/0000-0400 module, please refer to the official WAGO website or contact your authorized WAGO distributor. WAGO products are typically covered by a manufacturer's warranty against defects in materials and workmanship.

For technical support, product inquiries, or assistance with troubleshooting, please visit the official WAGO website or contact their customer service department. You can often find detailed product documentation, FAQs, and contact information on their site.

WAGO Official Websitio: www.wago.com