1. Introducción

The Logicbus Z-SG is a versatile conditioner and isolator designed for strain gauge applications. It features a single input compatible with 4 or 6-wire load cells, providing analog voltage or current output, and supports Modbus RTU communication. This module is ideal for industrial measurement and control systems requiring precise signal conditioning.

Las características principales incluyen:

- 1 input for 4 or 6-wire load cells with a configurable range of 1 to 64 mV/V.

- 1 analog output, configurable for current (0/4 to 20 mA) or voltage (0 to 5/10 Vdc).

- High 24-bit resolution for accurate measurements.

- Modbus RTU communication for integration into control systems (requires Z-PC-DINAL2-17.5).

- Flexible power supply options: 10 to 40 Vdc or 19 to 28 Vac.

Figura 1: Frente view of the Logicbus Z-SG Strain Gauge Input Module, showing terminal blocks and status indicators.

2. Configuración e instalación

Proper installation is crucial for the reliable operation of the Z-SG module. Ensure all connections are secure and follow local electrical codes.

2.1 Conexión de la fuente de alimentación

The Z-SG module accepts a wide range of power inputs. Connect the power supply to the designated terminals:

- Energía DC: 10 a 40 V CC

- Alimentación CA: 19 a 28 Vac

Asegúrese de que la fuente de alimentación cumpla con el volumen especificado.tage and current requirements to prevent damage to the module.

2.2 Strain Gauge Input Wiring

Connect your 4-wire or 6-wire load cell to the strain gauge input terminals. Refer to the module's labeling for correct pin assignments for excitation, signal, and sense lines.

Figura 2: Arriba view of the Z-SG module, illustrating the wiring terminals for power, strain gauge input, and communication.

2.3 Analog Output Wiring

Connect the analog output to your receiving device (e.g., PLC, data acquisition system). The output can be configured for either current or voltage:

- Salida actual: 0/4 a 20 mA

- Volumentage Salida: 0 to 5 Vdc or 0 to 10 Vdc

2.4 Comunicación Modbus RTU

For Modbus RTU communication, connect the module to a compatible RS-485 network. Note that a Z-PC-DINAL2-17.5 module may be required for proper integration. Refer to the Modbus communication protocol documentation for addressing and register details.

2.5 Configuración

The input range (1 to 64 mV/V) and output type (current/voltage) are configurable via the RS-232 port using free software provided by the manufacturer. Connect the module to a computer via RS-232 and use the software to set the desired parameters for your application.

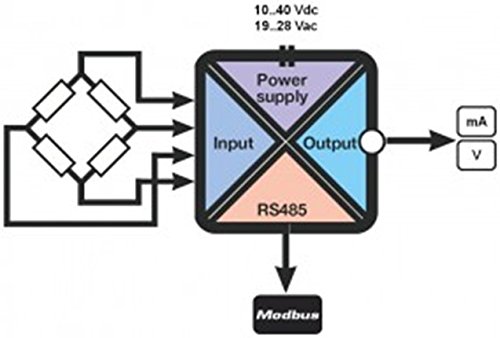

Figura 3: Functional block diagram illustrating the internal components and signal flow of the Z-SG module, including power supply, input, output, and Modbus communication.

3. Operación

Once properly installed and configured, the Z-SG module will convert the strain gauge signal into the specified analog output or transmit data via Modbus RTU.

3.1 Conversión de señal

The module continuously monitors the strain gauge input and converts the mV/V signal into a proportional analog current or voltage output, as configured. This output can then be read by a control system to monitor load or force.

3.2 Comunicación Modbus

For systems utilizing Modbus RTU, the module acts as a slave device, providing digital access to measured values and configuration parameters. Ensure your Modbus master device is correctly configured to communicate with the Z-SG module's address and baud rate.

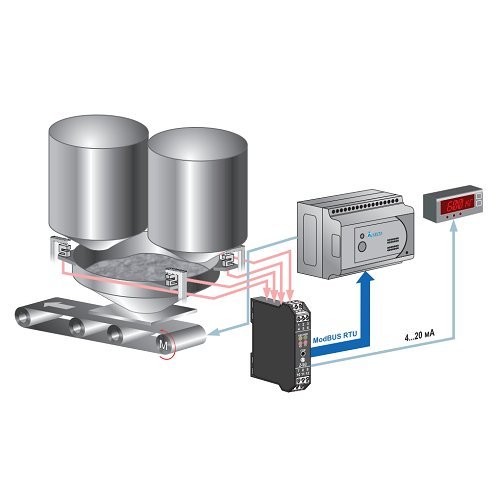

Figura 4: Example application diagram demonstrating the Z-SG module integrated into a weighing system, connecting load cells to a control unit via Modbus RTU and providing an analog output to a display.

4. Mantenimiento

The Logicbus Z-SG module is designed for long-term, reliable operation with minimal maintenance. However, periodic checks can help ensure optimal performance.

- Inspección visual: Periodically inspect the module and its connections for any signs of physical damage, loose wiring, or corrosion.

- Condiciones ambientales: Asegúrese de que el entorno operativo permanezca dentro de los rangos de temperatura y humedad especificados para evitar fallas prematuras.

- Limpieza: If necessary, gently clean the exterior of the module with a soft, dry cloth. Do not use harsh chemicals or abrasive materials.

- Recalibración: Depending on the application and required accuracy, periodic recalibration of the strain gauge system, including the Z-SG module, may be necessary. Refer to your system's calibration procedures.

5. Solución de problemas

If you encounter issues with your Z-SG module, consider the following troubleshooting steps:

- Sin energía: Verifique las conexiones de la fuente de alimentación y asegúrese de que el voltage is within the specified range (10-40 Vdc or 19-28 Vac). Verify that the power indicator LED on the module is illuminated.

- Salida incorrecta:

- Verify the strain gauge wiring for correct polarity and secure connections.

- Confirm the strain gauge is functioning correctly.

- Check the module's configuration via the RS-232 software to ensure the input range and output type are set correctly for your application.

- Ensure the receiving device (e.g., PLC) is correctly configured to read the analog output signal (current or voltagmi).

- Modbus Communication Issues:

- Verify RS-485 wiring, including termination resistors if necessary.

- Check the Modbus address and baud rate settings in both the Z-SG module (via configuration software) and the Modbus master device.

- Ensure the Z-PC-DINAL2-17.5 module, if used, is correctly installed and functioning.

- Observe the RX/TX indicator LEDs on the module for data transmission activity.

- Error Indicator (ERR LED): If the ERR LED is illuminated, consult the detailed product manual or contact technical support for specific error code interpretations.

Figura 5: Lado view of the Z-SG module, highlighting the status LEDs (ERR, PWR, RX, TX, COM) which provide visual feedback on the module's operational status and communication activity.

6. Especificaciones

| Característica | Valor |

|---|---|

| Número de modelo | Z-SG |

| Tipo de entrada | 1 input for 4 or 6-wire load cells |

| Rango de entrada | 1 ~ 64 mV/V (configurable) |

| Salida analógica | Configurable: 0/4 ~ 20 mA or 0 ~ 5/10 Vdc |

| Resolución | 24 bits |

| Comunicación | Modbus RTU (requires Z-PC-DINAL2-17.5 for full functionality) |

| Fuente de alimentación | 10 ~ 40 Vdc or 19 ~ 28 Vac |

| Dimensiones del producto | 6.89 x 3.94 x 4.41 pulgadas |

| Peso | 4.94 onzas |

| Fabricante | Seneca (Brand: Logicbus) |

7. Garantía y soporte

For information regarding product warranty, technical support, or additional documentation, please contact Logicbus Inc. or visit their official websitio.

Puede encontrar más información y datos de contacto en el Logicbus Store on Amazon.