1. Introducción

Thank you for choosing the Pretul BOAP-1/2P3 Electric Peripheral Water Pump. This manual provides essential information for the safe and efficient operation, installation, and maintenance of your pump. Please read this manual thoroughly before use and keep it for future reference.

Información importante de seguridad

ADVERTENCIA: No seguir estas instrucciones de seguridad podría provocar descargas eléctricas, incendios, lesiones graves o la muerte.

- Always disconnect the pump from the power supply before performing any maintenance or installation.

- Ensure the pump is installed in a covered, dry, and well-ventilated area.

- Do not operate the pump in environments where the ambient temperature exceeds 40°C (104°F).

- Ensure all electrical connections are properly insulated and protected from water.

- Do not run the pump dry. Always ensure the pump is completely filled with clean water before starting.

- Secure the pump horizontally on a flat surface using screws to prevent movement during operation.

- This pump is designed for pumping clean water only. Do not use it for flammable liquids, corrosive chemicals, or water containing abrasive particles.

2. Producto terminadoview

The Pretul BOAP-1/2P3 is a robust electric peripheral water pump designed to generate high pressure and lift water to significant altitudes. Its compact design and durable components ensure reliable performance.

Características principales:

- Generates greater pressure and raises water to a higher altitude compared to centrifugal pumps.

- Single-phase electric motor with aluminum coils for efficient operation.

- Durable brass impeller for constant pressure and long lifespan.

- Integrated heat shield for engine protection against overheating.

- Continuous working capacitor for stable performance.

Diagrama de componentes:

Descripción de la imagen: An exploded diagram of the Pretul BOAP-1/2P3 pump, highlighting key internal and external components. Labels indicate: Thermal protector, Continuous working capacitor, Motor with aluminum coils, Metal bearing for longer lifespan, Brass impeller for constant pressure, and Enclosed electric motor with external ventilation.

Descripción de la imagen: Two images showing the front and side views of the yellow Pretul BOAP-1/2P3 electric peripheral water pump. The pump has a black motor housing and a yellow pump body with a brass inlet/outlet.

3. Configuración e instalación

Proper installation is crucial for the pump's performance and longevity. Follow these guidelines carefully:

- Ubicación: Install the pump in a covered, dry, and well-ventilated area. Avoid direct exposure to rain, excessive humidity, or temperatures above 40°C (104°F).

- Montaje: Place the pump horizontally on a flat, stable surface. Secure the pump firmly using screws through the designated mounting holes to prevent vibration and movement during operation.

- Tubería: Connect the inlet pipe to your water source (e.g., tank or cistern) and the outlet pipe to your desired discharge point. Ensure all connections are airtight to prevent air leaks, which can affect pump performance. Use appropriate thread sealant.

- Cebado: Before the first use, or if the pump has run dry, completely fill the pump casing with clean water through the priming port. This ensures the pump is ready to create suction.

- Conexión eléctrica: Connect the pump to a suitable power supply as specified in the technical specifications. Ensure the voltage matches the pump's requirements. Use a grounded outlet and avoid extension cords if possible. If an extension cord is necessary, ensure it is rated for outdoor use and has adequate gauge.

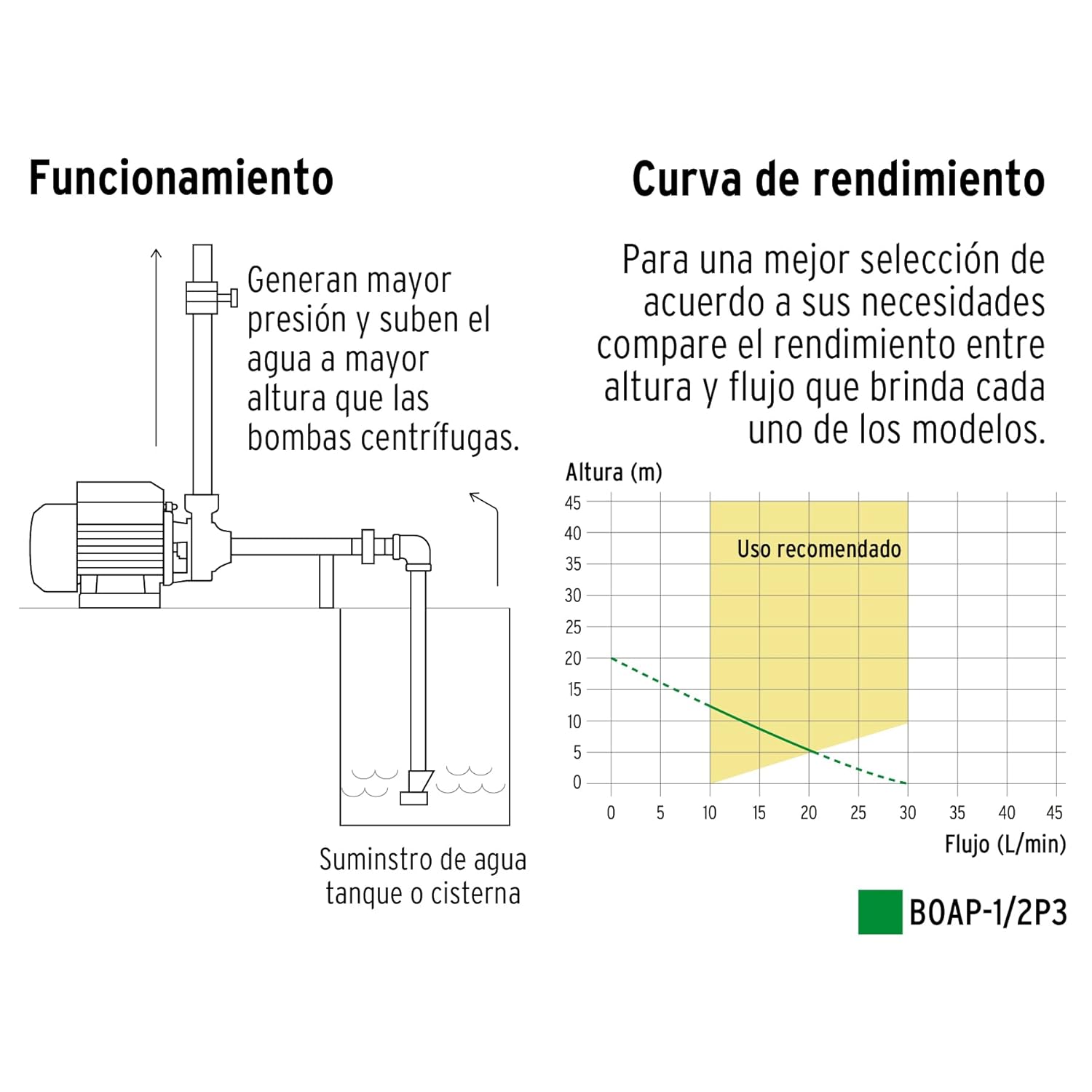

Descripción de la imagen: A diagram illustrating the pump's operation, showing it drawing water from a tank and raising it to a higher point. Alongside, a performance curve graph (Altura (m) vs. Flujo (L/min)) indicates the recommended use area for the BOAP-1/2P3 model, demonstrating its ability to generate pressure and flow.

Descripción de la imagen: An infographic displaying key recommendations for the pump: install in covered places, dry and well-ventilated, in environments not exceeding 40°C, fill completely with clean water before first use, and place horizontally on flat surfaces, securing with screws.

4. Instrucciones de funcionamiento

Una vez que la bomba esté correctamente instalada y cebada, puede comenzar a operar:

- Asegúrese de que todas las conexiones sean seguras y no haya fugas.

- Verifique que la bomba casing is completely filled with water.

- Connect the pump to the power supply. The pump will start operating.

- Monitor the pump during its initial operation to ensure proper water flow and pressure.

Ciclo de trabajo:

This pump is designed for intermittent use. To ensure optimal performance and longevity, adhere to the following duty cycle:

- Maximum continuous operation: 20 minutos.

- Minimum rest period after operation: 15 minutos.

- Do not operate the pump for more than 6 horas al día en total.

Adhering to this duty cycle prevents overheating and extends the life of the motor and components.

5. Mantenimiento

Regular maintenance ensures the efficient and safe operation of your pump. Always disconnect the pump from the power supply before performing any maintenance.

- Inspección regular: Periodically check the pump for any signs of damage, leaks, or unusual noises.

- Limpieza: Keep the pump exterior clean and free from dust and debris to ensure proper ventilation.

- Conexiones: Inspect all pipe connections and electrical wiring for tightness and integrity. Tighten any loose connections.

- Preparación para el invierno (si corresponde): If the pump is exposed to freezing temperatures, drain all water from the pump and pipes to prevent damage from ice expansion. Store in a dry, frost-free location.

6. Solución de problemas

Esta sección proporciona soluciones a problemas comunes que puede encontrar con su bomba.

| Problema | Posible causa | Solución |

|---|---|---|

| La bomba no arranca | No power; Motor overload; Damaged capacitor | Check power supply and circuit breaker; Allow motor to cool down; Contact qualified technician for capacitor replacement. |

| La bomba funciona pero no fluye agua | Pump not primed; Air leak in suction line; Clogged inlet/outlet; Water source empty | Re-prime the pump; Check all connections for leaks; Clear any blockages; Ensure water source is adequate. |

| Baja presión/flujo de agua | Partial blockage; Air in system; Worn impeller | Check for partial blockages; Bleed air from the system; Contact service for impeller inspection/replacement. |

| Ruido/vibración excesivos | Loose mounting; Air in pump; Bearing wear | Secure pump firmly; Re-prime the pump; Contact service for bearing inspection. |

Si el problema persiste después de intentar estas soluciones, comuníquese con el servicio de atención al cliente.

7. Especificaciones técnicas

| Especificación | Valor |

|---|---|

| Marca | Precio |

| Número de modelo | BOAP-1/2P3 |

| Color | Amarillo |

| Material | Latón |

| Estilo | Por encima del suelo |

| Dimensiones del producto (L x An x Al) | 29.3L x 12.7W x 24H Centímetros |

| Fuente de poder | Eléctrico con cable |

| Volumentage | 110 voltios |

| Peso del artículo | 3 kilogramo 550 gramo |

| Fabricante | Truper SA de CV |

Descripción de la imagen: A diagram showing the key dimensions of the Pretul BOAP-1/2P3 pump: Height (Alto) 15 cm, Base 12 cm, and Depth (Fondo) 24 cm.

8. Garantía y soporte

Información de garantía:

Pretul products are manufactured to high-quality standards. For specific warranty terms and conditions, please refer to the warranty card included with your product packaging or visit the official Pretul webSitio. Conserve su recibo de compra como comprobante para reclamaciones de garantía.

Atención al cliente:

If you have any questions, require technical assistance, or need to report an issue with your pump, please contact Pretul customer support. Contact details can typically be found on the product packaging or the official Pretul websitio.

When contacting support, please have your product model number (BOAP-1/2P3) and purchase details ready.